Hardcover Cover Printing.

Case Binding

Casebound books are commonly referred to as Hardcovers. Within case binding the styles are Casebound and Casewrapped.

Casebound books use traditional leather or book cloth material. They generally feature foil stamping on the front cover and spine for the title and author’s name.

Casewrapped books use a printed sheet in place of book cloth on the exterior. This allows for full color photos or graphics and the addition of film lamination for enhanced look and feel.

Essentially a three step process, case binding requires more material and labor than a softcover book’s Perfect Binding method. The result is a more substantial and durable book at the expense of longer production times and higher costs compared to other binding methods.

Cover Materials

If you opt for casewrapped hardcover book printing, we will print your design on our commercial presses. We will apply a thin film laminate to protect the covers in most scenarios. Your basic choices for lamination include the following:

- Gloss

- Satin

- Soft touch (provides a matte effect and a satiny, velvet-like texture).

Meanwhile, traditional casebound options include:

- Imitation leather

- Bonded leather

- Calfskin

- Several grades of book cloth such as Buckram and C-Cloth

There are a multitude of color choices within each type of material. Many of these options are produced in batches, so please call for availability if you have a specific request.

What's the difference between hardback and hardcover?

“Hardcover” and “hardback” are often used interchangeably. They refer to the same thing – a book bound with rigid covers. These covers are typically made of dense cardboard or binder’s board covered with cloth, leather or heavy paper.

Premium Hardcover Book Printing

At Bestbook, we take pride in providing our clients with high-quality book printing solutions at reasonable rates. We offer a wide range of book binding options, including casebound, casewrapped, coil bound, softcover and stitched, for any project.

We leverage our experience and expertise to craft books that our customers can be proud of. What’s more, we provide unmatched support, and we are more than happy to provide advice and tips on the best book binding options for your needs.

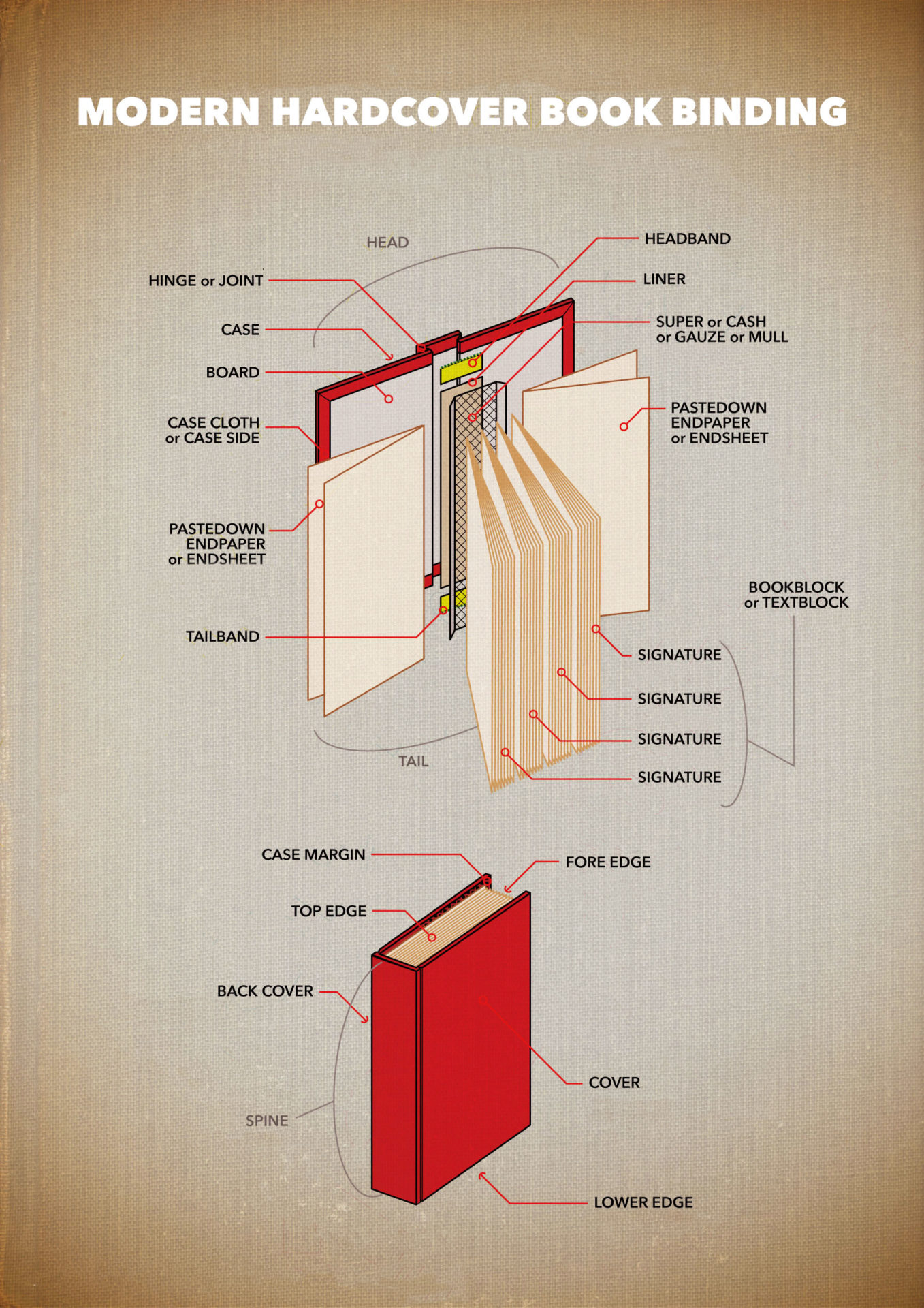

Casing-In

Casing-in involves putting the bookblock and the case together.

This is done by using endsheets, durable paper that are usually nonprinted. The endsheets are trimmed and folded to match the size of the bookblock. Then, they are glued to the inside of the case and the edge of the bookblock’s spine.

To ensure the glue sets well, the book is clamped and pressed in place. When the glue has set, the book can be foil-stamped or fitted with an optional dust jacket.

Printing for Self-Publishers

Self-publishing a book can be challenging, but we’re here to help make the printing part of the process as seamless and stress-free as possible. You can rely on us for quality services at reasonable rates, expert guidance on book specifications and even assistance with cover design if you need it.

Our goal is to give the book you’ve worked so hard on the beautiful, high-quality covers they deserve.

BUILDING THE CASE

A hardcover book is assembled from three main components: The case, the bookblock and the endsheets.

A bookblock is a collection of pages that have not yet been bound. Check out our Softcover page for more information on this process.

To create the case, three pieces of binder board reinforce the front and back covers as well as the spine. Leather or cloth is then wrapped around and glued to the pieces, accounting for thickness, overhang, and hinge areas.

It is now ready for the final stage in the hardcover book printing process: Casing-in.

Which genres are best suited for hardcover book printing?

There is no concrete rule as to which literary genres are best suited for hardcovers. The only real requirement is that your manuscript is at least 80 pages long.

Generally, however, it is best to choose hardcover book printing if the book is meant to be kept and treasured for years, such as yearbooks and art books. It’s also ideal for books that will likely experience frequent or rough handling, such as children’s books and coffee table books.

Additionally, a hardcover book lends an air of credibility to the work within. This makes it an ideal choice for authors with their first projects and for those who want to ensure the finished product has a professional look and feel.

Frequently Asked Questions For Hardcover Printing

It depends. At Bestbook Printing, we do not have standard pricing as all orders are custom projects. Our clients have unique book specifications, so every printing job is different. However, we do have a guide that details your book printing options and how they impact the final cost.

You may also reach out to us directly for an exact quote on your hardcover printing project.

As mentioned previously, digital printing is ideal for short runs, such as publishing a book. However, digital book covers are prone to problems such as cracking , crossgrain folding, delamination and peeling.

Hybrid printing is used at Bestbook to ensure our customers get the highest quality printed covers without the pitfalls of digital printing. What’s more, this option is more affordable than traditional offset printing–In fact, we price it the same as digital.